Ocean Farming: World's First Ocean Fish Farm

Producing animal protein from aquaculture uses fewer resources and is more environmentally-friendly than classic livestock methods. Since traditional fisheries are almost fully exploited, increased aquaculture production needs to play a major part in efforts to feed future generations.

The Norwegian Ministry of Fisheries and Coastal affairs recently decided to award development licences for aquaculture purposes. The objective was to spur new technology concepts that can deliver sufficient growth whilst also ensuring environmental sustainability.

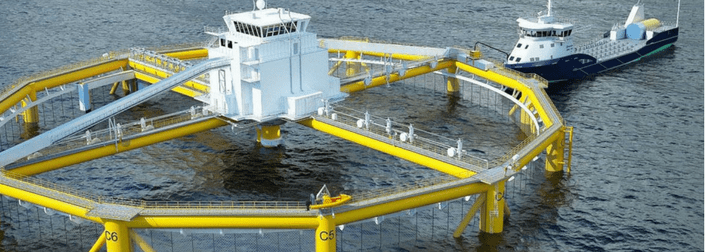

The Ocean Farming project answers this challenge, and SalMar ASA was the first seafood producer in Norway to be awarded this type of development licence. This year, Ocean Farming AS, a subsidiary of SalMar, took delivery of Ocean Farm 1: the world’s first offshore fish farm.

Applying Oil and Gas Project Management Practices

The Chairman of Ocean Farming, Gunnar Myrebøe, has a wealth of relevant experience, derived from project management in the oil and gas industry.

He had a clear idea of how his oil and gas project background would be applied to the delivery of the fish farm, using Safran's software and consulting expertise:

“There are many similarities between an oil and gas capital project and Ocean Farm 1. Therefore, we decided to take advantage of oil and gas project management best practices. Safran was a natural partner to engage, for both software and project planning expertise”.

Delivering Project Success

Despite challenges, the project has now been delivered on time and to budget, explains Arvid Hammernes, Managing Director of Ocean Farming:

“The development of this full-scale pilot ocean fish farm has been managed by four people. From owner SalMar’s Board decision in August 2015 until project completion, Ocean Farming has managed the project using the Safran Project planning tools. Through a short construction phase of 15 months, the facility was delivered in accordance with the tight schedule and investment estimate, allowing fish into the cages by the end of September 2017.”

Tracking of Schedule and Cost

A key objective was the tracking of three budgets: capital expenditures, management, and operations within the overall project plan. This was accomplished by creating a work breakdown structure (WBS), where each budget was tagged for easy filtering and reporting.

In the area of capital expenditures, the focus was the tracking of vendor contracts throughout the two-year project lifecycle. Senior Planner at Safran, Ketil Gjøvåg explains:

“In addition to planning and tracking the delivery schedule, a primary objective was to monitor the impact of Variation Order Requests (VORs) on schedule and cost. The board of directors required monthly project updates including S-curves, which were effectively produced in Safran Project.”

Meeting Milestones

Delivery slippage for some of the equipment did occur, as well as challenges with yard and transportation schedules. However, Safran Project provided stakeholders with clear, actionable insights of how the schedule was impacted, allowing management to proactively take action when slippages occurred. For example, to avoid transportation delays resulting in late installation, additional towing capacity was added to accelerate the tow from Malaysia to Norway.

Beyond Software

Ocean Farm 1 is the first project of its kind and so a number of unknowns were inevitably involved. To help all stakeholders hit milestones, reach objectives, and overcome struggles, Safran delivered more than just software.

Senior Planner at Safran, Ketil Gjøvåg, reflects upon how Safran acted in a consultancy capacity:

“Safran was called upon to deliver a complete project planning solution, including software and consultants. With our consulting team’s broad project planning experience and access to the Safran team’s product expertise, the customer received a complete project planning function without having to deal with different parties.”